Upgrade Your Compressed Air Blow Off System for Energy Savings

Are you considering upgrading your existing compressed air blow off system? Need more power or shorter cycle times? High efficiency centrifugal blowers can provide energy savings as well as a performance upgrade to your existing compressed air blow-off system for substantially less than your current system’s operating costs. See the details here.

A Closer look at Compressed Air Blow Off Claims

The makers of "Super" air knife products and other high pressure "airbar" manufacturers have recently invested significant effort in publicizing the relative merits of their products. With advertisements that apparently cite case studies, readers are often led to believe that actual systems were set up, critically evaluated, and proven to be “just as efficient” in drying, blowoff, and cooling applications - the applications where high-efficiency centrifugal blowers can easily outperform a high pressure airbar system, at much lower cost.See the details here.

Distributors

Process Air Solutions has distributors located across the United States and Canada to provide both sales and service for Vorton industrial air knives and centrifugal air blowers. We have 78 factory trained and certified distributors in 34 states, including Canada, that provide on-site application evaluation, air audits, unbiased equipment evalutions, on-site installation, and service/maintenance. Interested in becoming a distributor of Process Air Solutions and Vortron centrifugal blowers? Call 636-343-2021 and find out how to start selling the most efficient air knife system in the world!

Vortron AirPower™ Centrifugal Blowers

Vortron’s AirPower™ line of compact centrifugal blowers promises to raise the bar for industrial blower performance. Flow and pressure not attainable with competitive single stage products are now easily achieved. Three models are available: the flagship Z40e, the ultra efficient X40, and the scrappy J70. Each are specialists in their own right and are aerodynamically optimized for meeting specific flow and pressure requirements. All are clean sheet designs developed from the ground up to deliver best performance, best durability, and best efficiency available anywhere today. With peak isentropic efficiencies reaching 80%, no other compact blower product even comes close.

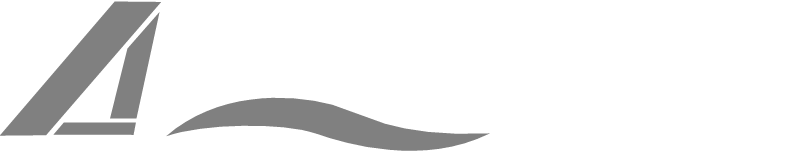

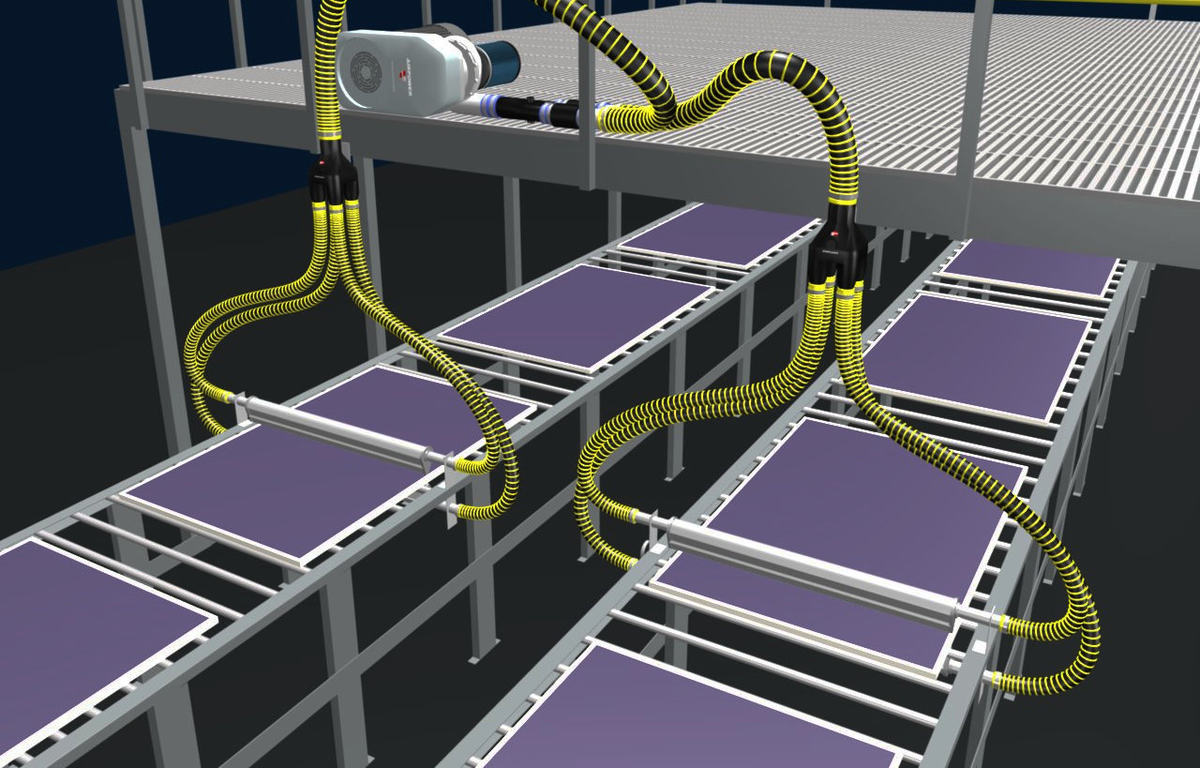

Air Knives

Process Air Solutions, providing total engineered solutions to your air movement and drying needs, can design complete air knife systems for a wide range of manufacturing applications. Air Superiority Air Knives are engineered to provide a highly concentrated laminar flow that exits the air knife nozzle as an uninterrupted continuous air curtain with a well controlled pattern. As an alternative to ineffective, low velocity, and/or low flow air blow off systems, Air Superiority Air Knife Systems provide an optimized balance of air velocity and mass flow. This balance is required for effective and efficient performance in applications such as continuous coating control, cooling (air quench) and debris removal, as well as air drying and many others.